How do we choose the best software for sheet metal design?

Choosing the best sheet metal design software is the most crucial element in sheet metal fabrication.

As the name implies, sheet metal must be formed into flat, thin pieces by combining a small amount of aluminum, steel, brass, copper, and various other materials. It can be cut precisely and formed into sheets, plates, or foils due to its distinctive features.

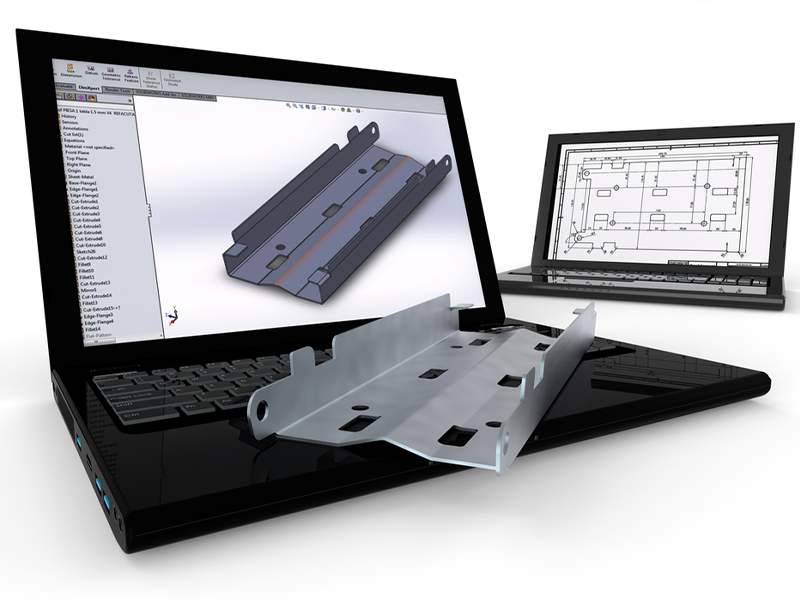

Sheet metal design involves shaping sheet metal into equipment, parts, assemblies, and products. Alibre Design software automates this process by enabling the automation of sheet metal design, nesting components, and generating CNC tool paths. Specifically designed for sheet metal, the software supports the engineering, modification, and optimization of sheet metal parts, along with creating manufacturing instructions and documentation.

In this article, we’re delving into the sheet metal manufacturing industry in the context of how metal design software can help guide this sector toward the future.

Why do you choose the best software for sheet metal design ?

Alibre's sheet metal design software integrates both 2D and 3D design features, enabling engineers and designers to craft accurate models of sheet metal components. Users can specify details like material thickness, bend allowances, hole sizes, and other geometric features crucial for sheet metal fabrication.

Simplify your design with Alibre software, the best CAD software for metal fabrication process. It seamlessly connects 2D and 3D workflows, allowing you to efficiently create, modify, and document sheet metal designs. This streamlined approach facilitates the swift transition of flat patterns into production.

Let us briefly list the top 5 benefits of choosing sheet metal design.

- Sheet metal products are relatively less expensive and more straightforward to manufacture but are used in forming processes.

- Manufacturing can be done on a smaller scale, not requiring a high-end machine. A hydraulic press uses various tools to form a sheet metal product for many processes.

- Cutting technology for CNC plasma has been added to the capabilities of sheet metal thanks to its precision and automation—cutting off any form.

- Sheet metal works efficiently because of the more straightforward procedures you have for drilling a hole, such as in the case of solids. However, in the case of sheet metal, you need to punch holes. Drilling is necessary to create a slot within a solid, but in sheet metal, CNC plasma cutting or a punch will complete the task.

- It is said that the weight of sheet metal-designed products is much smaller, which is the reason most enclosures are constructed of sheet metal, and most aluminum sheets are utilized because of their higher strength-to-weight ratio.

Alibre Design Software - The best CAD software for your Sheet Metal Design Needs

There are a variety of products that offer procedures that are related to sheet metal manufacturing design and other similar businesses. Manufacturers and engineers have been using specific drawing tools that create design information.

Compared to the real world (solid form), sheet metal pieces are usually created by 2D models using processes like cutting, bending, and welding.

Since sheet metal design differs from solid modeling, software designers should incorporate specific regulations into their designs. This allows the designer to convert the programmed format into metal sheet components.

Furthermore, by using the appropriate tools for design and modeling, you can reduce or eliminate mistakes and get your design to life promptly. Design flaws and delays typically cause the loss of time, waste of materials, and a decrease in profitability, which is detrimental to the company.

For a business that struggles to deal with shrinking resources, choosing the best software for CAD can be an issue of life or death. Utilizing these modern tools will help reduce changes in engineering (ECO) design errors and other mistakes that designers often create.

Here are five things to keep in mind when choosing the best CAD software for creating sheet metal

1. Sheet Metal Design Ability

Designers and engineers who can design sheet metal should ensure that the CAD program they purchase is compatible with their current software.Otherwise, the buyer could begin with a new project. The initial goal was to establish sheet metal compatibility with the CAD layout of the purchase. But, no one CAD software can satisfy all of your design requirements. This is the reality that everyone should accept.

Additionally, some of the most modern CAD tools available today might work differently than your current ones. There are now a variety of CAD modeling platforms with sheet metal design capabilities that can be used to create 3D models. Several CAD platforms can transform the solid model into metal sheets and add plane patterns.

2. DFM Regulations

A CAD system that is designed with manufacturing (DFM) capabilities will boost efficiency while also reducing the amount of time wasted. The DFM function should be utilized to create sheet metal products since it can ensure the plan's operation before submitting an item to a workshop.

The latest technology in CAD allows designers to revise their designs and conduct final checks before the actual production.

3. Ability to Handle Different File Formats

Engineers and designers should remember they are not alone. One of the primary reasons to choose a CAD system for designing sheet metal is that it can manage and store different file formats. Even the most prominent companies involved in this kind of business ought to adhere to this method, as they could have a wide variety of software suppliers that will help them make a lot of designs.

4. More Effective and Lasting Tools

Selecting a program specifically designed for processing sheet metal is the best reason. Although the program is written in 3D, most sheet metal designs typically include 2D engineering sketches. However, the 3D model may not accurately represent other specifications and dimensions (such as tolerances, surface finishes, etc. ). More specifics are required after the foundation has been laid.

5. Shorter Program Learning Time

Select a program that users can master in the shortest period ("short the learning curve"). If the user can't figure out how to integrate it properly in their local system, then even the most sophisticated CAD software in the world might need to be more powerful.

Alibre Design software offers numerous advantages to users engaged in sheet metal fabrication and manufacturing. Key benefits encompass optimized material usage, time efficiency, enhanced production processes, cost savings, seamless design-to-manufacturing integration, and compatibility with diverse fabrication methods.

Try our metal fabrication design software free

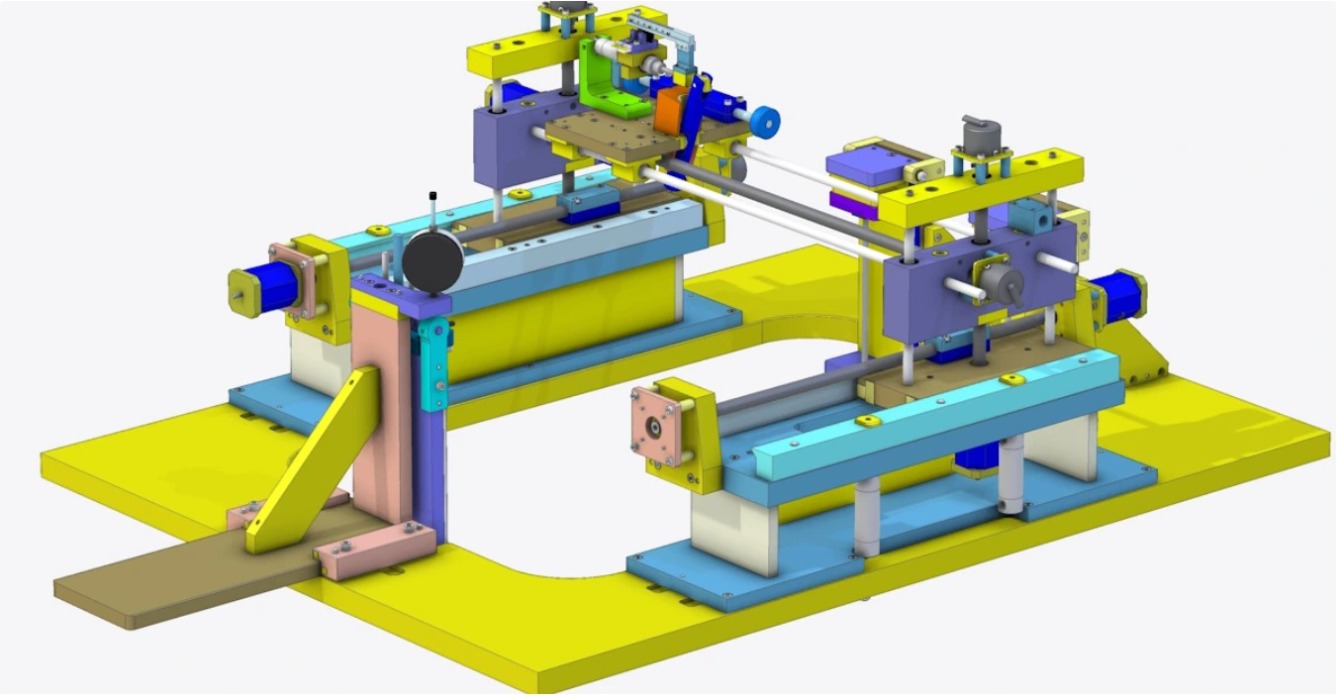

What are the production methods utilized in crafting sheet metal designs?

Water Jet Cutting:

Utilizing pressurized water mixed with abrasives, this method can efficiently cut through a variety of materials including stainless steel, Inconel, titanium, aluminum, tool steel, ceramics, granite, and armor plate, resulting in a clean edge finish.

Laser Cutting:

Involving the transmission of a gas laser, like CO2, through a precisely guided beam directed at the material, laser cutting achieves an exceptionally high level of precision.

Plasma Cutting:

The plasma process employs electrically conductive gas to transfer energy from a torch to the material, making it suitable for cutting metals like stainless steel, aluminum, and copper, especially those that cannot be flame cut.

Wrapping Up

As the challenges increase and the need for accuracy and efficiency increases, businesses must remain ahead of the technological curve.

Alibre Design is the best software for sheet metal design. This 3D CAD Software promises improved efficiency, reduced errors, and enhanced collaboration.

Are you ready to propel your processes for production ahead?

Contact Alibre today to take the sheet metal production process to new levels.

Last updated : 1 month, 3 weeks ago